News about wood gasification | Spanner Re²

Find out everything about wood gasification in our blog.

In this blog you will also get the latest information about our company Spanner Re² GmbH.

We say THANK YOU and wish everyone a Merry Christmas and a Happy New Year!

Dear business partners, valued customers and interested,

we are separating the domains of the divisions of the Spanner-Group into the Automotive Supplier and Renewable Energies divisions. For this purpose, we will use our existing domain @holz-kraft.de for the Renewable Energies division in the future. This will only change our email suffix from @spanner to @holz-kraft.de. As of 01.12.2023, all email addresses on @spanner.de have been deactivated. These will no longer be delivered. Please note our new email addresses on @holz-kraft.de!

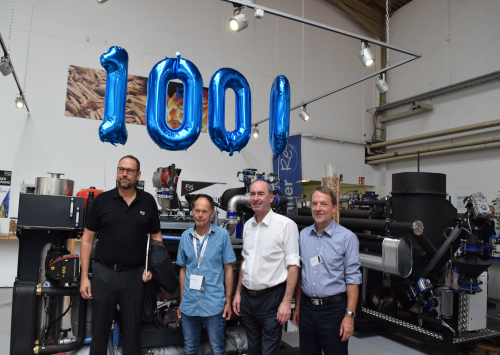

Last Friday, Spanner Re² GmbH held a big anniversary celebration with an open day to mark the 1000th biomass CHP power plant delivered. Minister of State and Deputy Minister President Hubert Aiwanger (member of the state parliament), was a guest and spoke very clearly in favour of wood gasification technology.

"Inspire by doing" - that is the credo of the Deggendorf-based association Technik für Kinder e.V. (TfK). Re² has supported the non-profit association since the very beginning. With its diverse projects, TfK enables over 7,000 children to discover the exciting world of technology every year.

Standstill is a foreign word for Spanner Re² GmbH. Thus, we are continuously working on our globally proven technology for generating electricity and heat from residual materials. We are pleased that our research and development activities have been awarded the BSFZ Seal 2023.

Sensational runtimes of the CHP plants at the Kirchschlag CHP plant with over 93%

Since 2020, five wood-fired power plants from Spanner Re² GmbH with a total output of 340 kilowatts of electricity and 615 kilowatts of thermal energy have been in operation in the Kirchschlag municipality's combined heat and power plant, which was built specifically for the project. The proven Re² systems produce electricity and heat according to the principle of combined heat and power (CHP). A thermochemical process is used to generate a particularly clean wood gas from wood chips, which is converted into electricity in a downstream combined heat and power unit (CHP). The plants have produced around 7,500 megawatt hours of electricity and over 16,000 megawatt hours of heat since 2020 (Stand 06/2023). With over 23,400 operating hours per plant, plant availability since commissioning is over 93 per cent, which significantly exceeds the municipality's 85 per cent target.

The 1000th biomass power plant was recently produced at the Lower Bavarian plant of Spanner Re² GmbH in Neufahrn. The biomass power plant will be installed in a dairy in German, beside 11 other plants from Re². With the conversion to the proven power plants of Spanner Re² GmbH, the dairy cooperative will be completely self-sufficient in energy in the future and this will be 100% renewable energy.

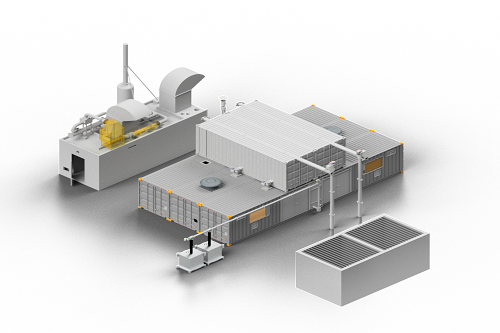

With the two new plant models, Re² is expanding its product portfolio in the large-scale plant sector. The HKA 300 consists of one engine and four wood gasifiers and the HKA 700 of one engine and 10 gasifiers. The modular gas power plants can be scaled up to several megawatts as required and are supplied as complete plants, including peripherals such as fuel drying, suitable discharge and conveying technology, and intelligent control technology.