Wood gasifiers supply energy

Shortly behind Meran, in Riffan, lies Pepi Hofer's commercial building. Cleverly integrated into the underground parking, Pepi Hofer combines the two HKA 45 plants from Spanner Re² GmbH with a hopper for delivered wood chips and the storage hopper with built-in push floor and transverse auger discharge. There is actually not much to see in the basement of the building except for the integrated plant room. Another short glance into the storage hopper filled with wood chips - and that was it.

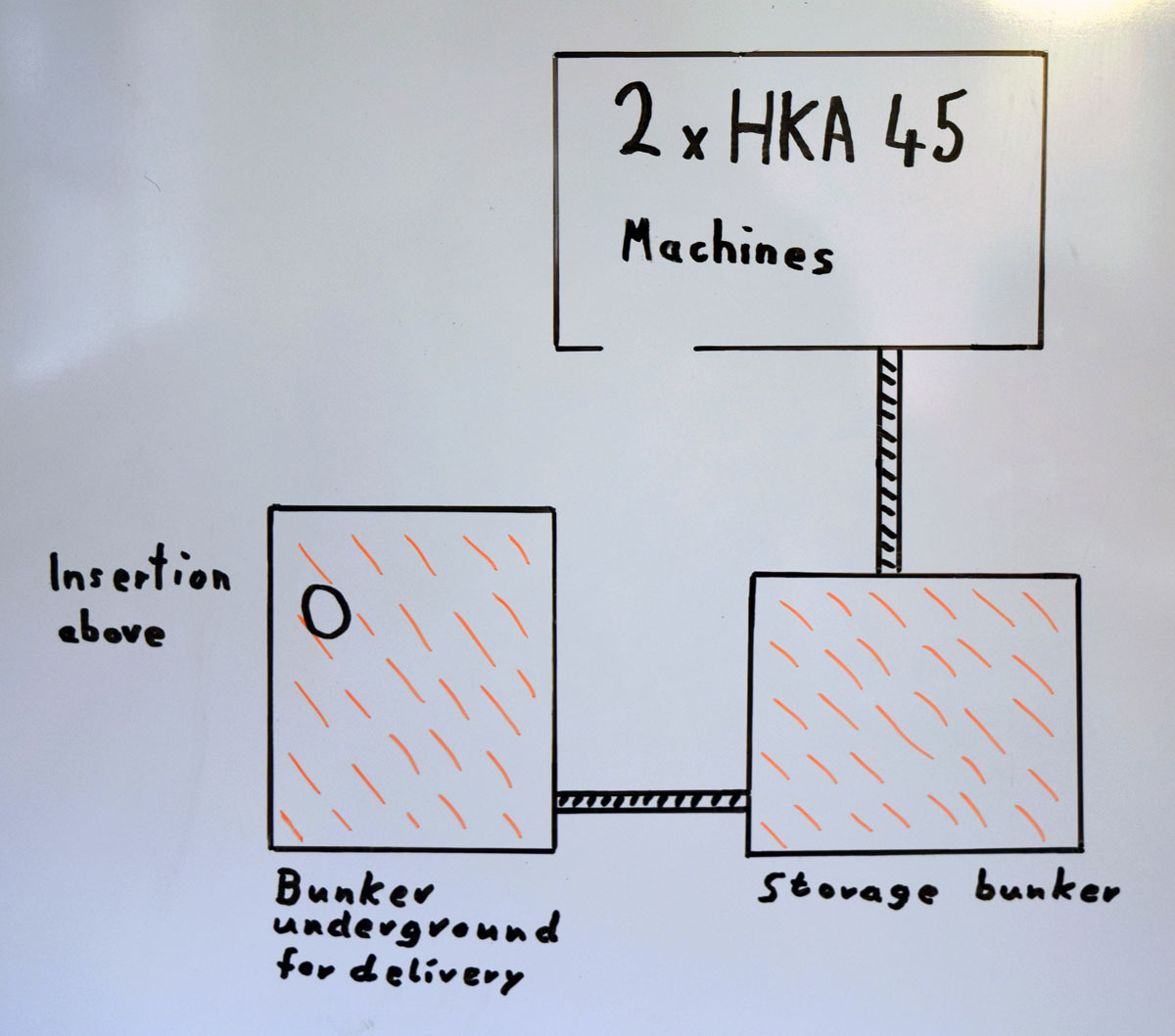

A facing in the underground parking for the worm conveyor system and a blind cover on the surface for the filling partially show the way of the wood chips from the delivery to the wood gasifiers.

Hubert Weissteiner integrated the whole system for the wood cogeneration plants and it works great.

Wood chip management:

Pepi Hofer has minimised the wood chip issue as much as possible. Every week, 48 m³ of good quality dry wood chips are delivered. Pepi Hofer makes absolutely sure that the fragmented sizes are between 3 and 5 cm, that they have a maximum residual moisture of 10 % and include no more than 20 % of fines (note: The operator's maximum requirements may differ from the requirements of the Firma Spanner Re²).

The generally good wood chip quality is immediately evidenced in the smooth operation of the plant. The plants that were put into operation in the beginning of 2012, boast a plant utilisation of 91.3 % per year with about 8,000 hours of operation. It has to be noted that plant shutdowns are usually compensated by the second plant; the utilisation of the heat generation is therefore even higher than in the case of single plants.

Plant schematic:

Key data of wood gasifier reference:

Hopper for the buffering of delivered, ready-to-use wood chips: approx. 50 m³

Wood chip hopper with push floor for buffering the wood chip fuel: 80 - 90 m³

Conversation with Pepi Hofer about the Biomass CHP plant data:

Hi Pepi, we are here in the basement of your commercial building. Your wood cogeneration plants appear to be in a very well-kept plant room. What do you do with the large amount of heat that the two 45 kW plants produce?

I require about 70,000 kWh of heat energy per year. A DESPAR supermarket is housed inside the commercial building; the community doctor, a pediatrician, a beauty studio, the shoe orthopaedist and a small apartment. A local heat network connected to the brother's nearby hotel (35 beds) is already in the planning. A heat pump has been installed in addition to the Spanner Re² wood cogeneration plants, which uses the heat of the river water.

How did you find out about the wood gas technology from Spanner Re²?

I have travelled about 50,000 km by car in Europe and have visited manufacturers and reference plants for the generation of energy. I wanted to become independent from fossil fuels. At one point I found out about the wood gasification technology and electricity and heat generated from wood chips. What followed were two years of slow-moving approval processes from Bozen to Rome; after the "yes" it then all started...

Photos of the Biomass CHP plant: (Click on the photos to magnify)

https://www.holz-kraft.com/en/references/references-by-countries/italy/276-pepi-hofer.html?tmpl=component&print=1&layout=default&page=#sigProIdfd4e2db3d5