News about wood gasification | Spanner Re²

Find out everything about wood gasification in our blog.

In this blog you will also get the latest information about our company Spanner Re² GmbH.

Dear business partners, valued customers and interested parties,

we are separating the domains of the divisions of the Spanner-Group into the Automotive Supplier and Renewable Energies divisions. For this purpose, we will use our existing domain @holz-kraft.de for the Renewable Energies division in the future. This will only change our email suffix from @spanner to @holz-kraft.de. Of course, you can reach us as usual through the communication channels you are familiar with.

In september 2022, Dr Harald Dinter took up his position as managing director of Spanner Re² GmbH. He strengthens and complements the management team around the long-standing CEO Thomas Bleul and Helmut Spanner. Dr Harald Dinter has already been involved with the topic of renewable energies for many years and is ideally suited for his new task due to his professional background as well as his personal strengths.

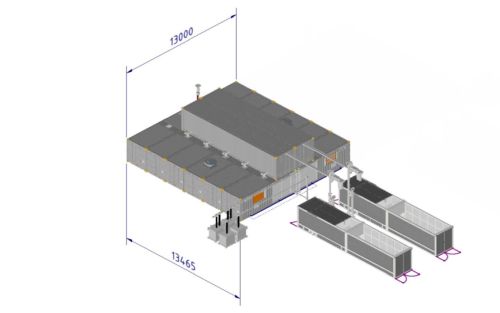

Another large scale project with biomass power plants from Spanner Re² GmbH goes on grid in Japan and also protects the population from allergies by reducing sickle fir pollen. With around 1.8 MW of electricity, it is one of Spanner Re²'s largest projects and once again demonstrates the know-how of the market leader.

To prevent the standstill of productions that only work with natural gas, wood-fired power plants from Spanner Re² GmbH offer an inexpensive alternative.

Mafia Island is an insider tip among travel lovers when heading to Tanzania. Along with tourism, rural Sowoe forestry is one of the dominant branches of industry on the island. Above all, coconut and cashew nut plantations determine the vegetation of the industrious islanders. The valuable wood is also used in the furniture industry.

Diesel aggregate with 400 kW electrical output is supported in the

base load by two HKA70

For better understanding, a capacity utilization of 100% per year was calculated.

Rising oil prices and the CO2 problem - reasons that, more than ever, encourage a rethinking of energy production. With CO2-neutral wood gas CHPs from Spanner Re², there is an alternative: Generate decentralized electricity and heat for your company from wood.

For 35 years, the company Biogas Hochreiter GmbH from Schnaitsee in Upper Bavaria has been operating globally functioning and, above all, highly reliable plant systems in the field of wood gas technology. In particular, combined heat and power plants with 300kW electrical output in combination with the proven wood gasification systems from Spanner Re² GmbH promises a highly efficient solution in the area of large-scale systems with CO2-neutral wood gas technology.