In addition to the construction of biomass power plants and biomass boilers, we are specialists in the production of wood chip drying systems.

With our wood chip drying technology, the energy yield of the fuel can be significantly increased. Drying systems from Spanner Re² not only reduce the water content of the wood chips, it also minimise the fine fraction and mineral pollutions by integrated sieve elements. This means that you can refine almost any natural wood or wood wastes into a high-quality fuel. The processed material is optimally matched to the requirements of the biomass power plant and ensures a particularly efficient wood gasification operation.

We offer various wood chip drying technologies - from fully automated wood chip dryers to simple wood chip drying systems with sloping ground dryer.

Fully automated wood chip drying with Spanner Re² push floor dryer

- Fully automated wood chip drying without "wet nests"

- Space saving through a compact and robust construction

- Adjustable residual moisture

- Easy access via control panel, PC or Smartphone

- 95% reduced dust development

Included:

- Storage bunker

- Warm air supply

- Fine particle screening and fine particle removal

- Thrust conveyor technology with robust hydraulic system

- Feeding via conveyor belts or conveyor augers

- Technical room with intelligent control

| Technical data - wood chip drying systems | Typ 6SBT-5 / 6SBT-25 / 12SBT-25 | |||

| Drying output per day* | Up to 5 – 35 m³ dried wood chips | |||

| Capacity storage bunker | 6 m: ~ 2-16 m³ 12 m: ~ 25 m³ | |||

| Layer height of the wood chips | 0,4 m – 0,6 m | |||

| dimensions | 6 m: 6 m x 2,4 m 2,6 m 12 m: 12 m x 2,4 m x 2,6 m | |||

*depending on design and type of drying system, and also depending on wood chips quality (humidity)

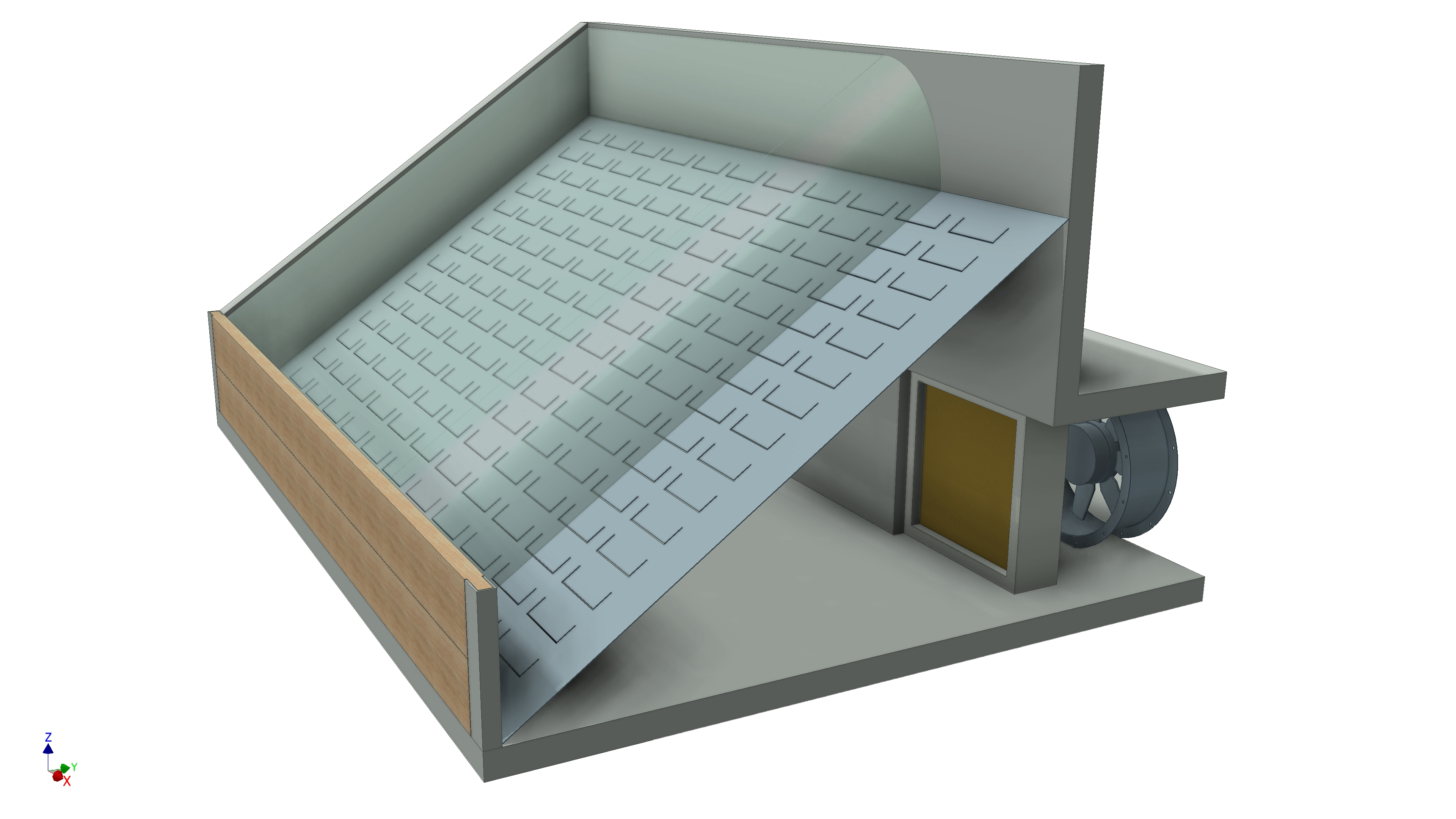

Spanner Re² sloping ground dryer - flexible and cost-effective

With the sloping floor dryer, the wood chips are distributed over a large area on an angled floor (angle approx. 40° to 45°). The slanted floor consists of air-permeable metal sheets.

The warm air flows through the air slits of the sheets from below, drying the wood chips above. The warm air can either be taken from the installation room of the wood gasifier system or generated by a heat exchanger. The heat exchanger can also be operated manually and, in the ideal case, is only switched on during the cold season (assuming that the sloping floor is directly connected to the plant room). The wood chips are distributed on the inclined floor with a front loader or wheel loader, for example. In the course of the drying process, wet wood chips can be re-layered from the bottom to the top or dry wood chips can be transported to a storage bunker for storage.

The sloping ground dryer is a particularly cost-effective type of wood chip drying technology and it has more space available for storage and drying. Depending on the customer's request, the wood chips can also be removed via a screw conveyor.

Get in touch with us

Do you have any questions or would you like to see our wood chip drying technology in practice? Then fill out the contact form below and we will get back to you straight away.

Gallery of wood chip drying technologies from Spanner Re²:

-

wood chips filling funnel wood chips filling funnel

wood chips filling funnel wood chips filling funnel -

forty feet drying technology forty feet drying technology

forty feet drying technology forty feet drying technology -

Control system and maintenance window Control system and maintenance window

Control system and maintenance window Control system and maintenance window -

drying technology with moving floor drying technology with moving floor

drying technology with moving floor drying technology with moving floor -

pushfloordryer grafic pushfloordryer grafic

pushfloordryer grafic pushfloordryer grafic -

truck with drying technology truck with drying technology

truck with drying technology truck with drying technology -

twenty feet drying technology twenty feet drying technology

twenty feet drying technology twenty feet drying technology -

wood chips drying discharge system wood chips drying discharge system

wood chips drying discharge system wood chips drying discharge system -

Vertical wood chips conveying system Vertical wood chips conveying system

Vertical wood chips conveying system Vertical wood chips conveying system -

wood chips bunker wood chips bunker

wood chips bunker wood chips bunker -

wood chips drying Control panel wood chips drying Control panel

wood chips drying Control panel wood chips drying Control panel

https://www.holz-kraft.com/en/products/drying-technology.html#sigProIde30d768a1b