Press | Spanner Re² GmbH

Find out in our press releases actual topics about wood gasification and Spanner Re² GmbH.

If you need further information or pictures, please contact us.

We will be happy to help you: This email address is being protected from spambots. You need JavaScript enabled to view it.

In May, the 1000th biomass power plant was produced at the Lower Bavarian plant in Neufahrn. The biomass-based CHP plant is installed in a dairy in the Allgäu region, alongside 11 other Re² biomass power plants.

Spanner Re²'s largest biomass power plant with approximately 2 MW of electricity and over 4,4 MW of thermical is located in Japanese Azumino City, Nagano Prefecture. Another particularly sustainable aspect is that not only heat and electricity are generated regeneratively, but CO2 present in the exhaust is used in tomato cultivation via a special purification process that positively influences the photosynthesis processes of the tomato plants. This is the first gasification power generation system of its kind in Japan.

In 2020 Spanner Re² achieved a very solid business year despite Corona-related challenges. Turnover increased by 40 percent compared to the previous year.

The Lower Austrian municipality of Kirchschlag is setting the course for an energy independent future and is a leading role model for many other municipalities.

Since the end of 2019, family-run bakery "Löwenbäcker Schaper" from German Brunswic have been using a Spanner Re² biomass power plant to generate electricity and heat from shredded pallets that accumulate during bakery operations.

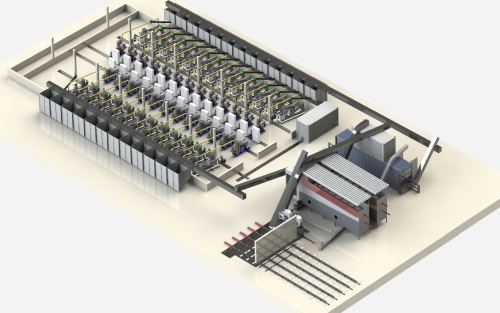

At the end of this year, the Lower Bavarian plant manufacturer Spanner Re² GmbH delivered 28 wood power plants with a total output of 1.75 MWel and over 3 MWth with complete wood chip logistics as well as conveyor and discharge technology to Japan.

Large cogeneration project in Japan is expanded by 20 Spanner Re² systems

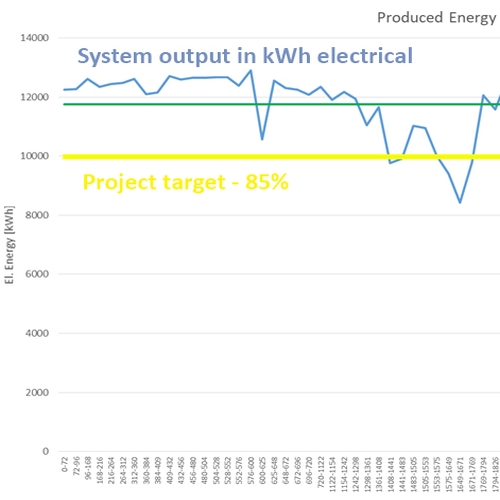

Since the beginning of 2019, only ten, then twenty wood gasifiers from Spanner Re² GmbH including peripherals with above-average plant runtimes have been in operation. By the end of this year, the customer will install additional wood gasifiers with an electrical output of 1 MW.

Ten wood-fired power plants with 500 kWel and peripherals of the Lower Bavarian wood gasification manufacturer Spanner Re² GmbH went into operation in March this year. The scheduled mileage of wood-based CHP plants of 7,500 hours per year has been surpassed by more than 18 percent since commissioning.