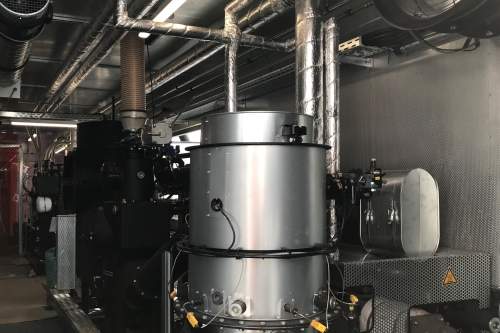

Wood gasifier in Germany | References

Wood chips in the front, energy out the back to the households

In the district of Lohen in the Upper Bavarian municipality of Schechen, district of Rosenheim, 10 households look forward to their constant energy supply from their own village every day. The local wood-fired power plant is part of the Weber Sepp's operations and supplies 9 surrounding households as well as its own residential building and the Theaterstadl with CO2-neutral thermal energy based on wood gasification technology from wood chips as fuel.

CO2-neutral energy supply for Diemelstadt

CO2-neutral energy supply for Diemelstadt

A fire in 2015 led to the relocation of the wood power plant from Warburg to Diemelstadt. The operator Hubertus Wiemers sees his mission in the CO2-neutral generation of electricity and heat using wood gas technology from Spanner Re² GmbH. Diemelstadt has set itself the task of climate protection and would like to make an active contribution to this by means of renewable energies.

Bakery maximises resources to generate electricity, heat and hot water from wooden pallets

Quality and regionality are top prorities for the family-run bakery "Löwenbäcker Schaper" from German Brunswick, both in their bakery and for their energy supply. Since the end of last year, they have been using a Spanner Re² system to generate electricity and heat from shredded pallets that accumulate during bakery operations. Their approach to energy generation is sustainable and adds optimal value at the same time.

Sawmill reduces energy costs with wood gasifier

Sawmill reduces energy costs with wood gasifier

Since 2014 the electrical power and the heat demand of Mr. Hagedorns sawmill gets produced by a Biomass CHP HKA 45. The Hagedorn Sawmill in North Rhine-Westphalia has six drying chambers with 400 m³ of a sawn wood that is brought to use wet. The electric and thermal energy that is necessary to run the sawmill is vast. With that in mind, family Hagedorn has been thinking about producing energy out of their accruing wood chips for quite a long time.

Robert Christl runs a sawmill north west of Landshut, in Weihmichl. To meet the huge electricity and heat demands of his sawmill Robert Christl installed a Biomass CHP from Re² in 2014. Even although his energy demands are high his costs are minimal because he uses all the waste wood products that accrue from wood processing at the sawmill as fuel for the CPH.

Robert Christl runs a sawmill north west of Landshut, in Weihmichl. To meet the huge electricity and heat demands of his sawmill Robert Christl installed a Biomass CHP from Re² in 2014. Even although his energy demands are high his costs are minimal because he uses all the waste wood products that accrue from wood processing at the sawmill as fuel for the CPH.

Repowering of wood gas CHP engine to 3,000 rpm

Since 2017, the wood gas CHP's 5.7 L engine has been running at 3,000 rpm - and very successfully. In February the engine already reached over 20,000 operating hours.

“Conventional energy generation with the negative results, independency of costs and the central energy politics made me thoughtful. With the HKA 10 we can produce electricity and heat anytime with our own wood and are independent. A good feeling.”, says Andreas Huber.

“Conventional energy generation with the negative results, independency of costs and the central energy politics made me thoughtful. With the HKA 10 we can produce electricity and heat anytime with our own wood and are independent. A good feeling.”, says Andreas Huber.

Andreas Huber was determined to find an electricity and heat solution for his farm and buildings that was self-sufficient and cost-effective. In 2016, after a long search to find the best technology he invested in a Biomass CHP from Re². The HKA 10 CHP unit produces electricity to cover Andreas´s own needs as well as supplying the power supply system which he receives payment for according to renewable energy law. The heat produced by the HKA 10 is used for heating Andreas´s buildings and also for drying the wood chip.

Wood gasifier supplies community with electricity and heat

Wood gasifier supplies community with electricity and heat

140 people live and work in the Münzinghof village community. Around half of these have a physical or intellectual disability. The aim is to provide these fellow residents with a familiar community, to work with them, and to help them develop at a personal level. The village consists of residential homes which operate based on sustainable principles. Businesses include a nursery, dairy farming, a cheese dairy, a bakery, and woodworking and metalworking shops.

Wood gasifier supplies local heating network with heat from wood chips

Wood gasifier supplies local heating network with heat from wood chips

The Wäsler family, which owns the sanitation and heating construction firm of the same name, has been operating a local district heating network to heat 13 commercial units and 27 private households in Steinhausen, near Glonn. The network is 870 metres long, and is supplied by a Biomass CHP with an output of 45 kWel and 120 kWth. The generated electricity is fed into the public pipe network. The wood gasifier operates for around 6,000 hours a year.